PRODUCTS

Software

Overview

Explore our range of motion capture software solutions.

CORTEX

Advanced yet intutive. This motion capture solution is ideal for scientific and healthcare environments.

RIG SOLVER

The skeleton solver and data clean-up tools from Cortex, in a stand-alone module

BASIX© GO

Our lightweight mocap solution is ideal for animation and character design.

Integrations

Our tech is widely integrated with equipment from world-leading hardware and software partners.

Hardware

Packages

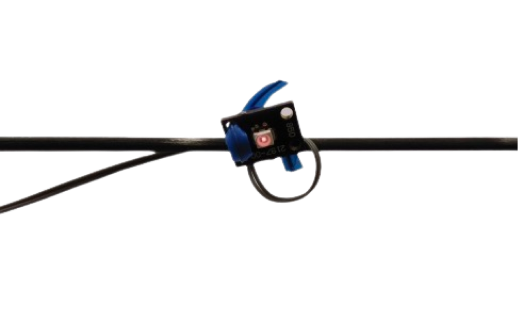

Basix "Lite" mocap KIT

12 cameras, 6 markers. Setup in under a minute. This system of hardware and software is ideal for quick mocap.

Vespa drone tracking kit

This is our ready-to-use drone tracking kit. It includes Cortex, 2 Firefly active marker kits, and 12 Lhotse cameras.

Custom setup

Not sure what you need? Our team can help you work it out.

APPLICATION

ANIMAL STUDIES

Movement tracking and analysis solutions for animals

Animation & game development

Flexible mocap to suit your needs (and budget)

Clinical Evaluation

Clinical gait and movement analysis

Research

Accurate tracking solutions for even the most subtle movements

Rigid object & robotic tracking

Robot, drones and other rigid object tracking

Sports Performance

Full body analysis to enhance sports performance

Studio Camera Tracking

The ultimate studio camera tracking solution for broadcast

VR Gaming & Training

Create immersive, real-time 3D virtual reality environments

RESOURCES

PRICING

Support

Events

ABOUT

OUR STORY

For over 40 years we have been working hard to deliver accurate, robust and innovative mocap. Read our story.

INTEGRATIONS

Our technology integrates with an array of leading software and hardware. Explore them here.

DISTRIBUTORS

We have partnerships with distributors around the globe. Find a local reseller here, or apply to become one.